5 Common Timber Framing Mistakes to Avoid

The small things matter. After all, they create the bigger picture. The framing of the building may seem small, but it is essentially the skeleton and foundation of the overall design. Ensuring that your initial structure is reliable helps you avoid other issues that may come.

When building your structure, keep your team on the same page and make sure they have the skills to achieve your design. Keep reading to learn some of the most common framing mistakes, and consider a few of our tips for optimizing your building operation.

Common Wood Framing Mistakes

Whether you’re building a home, shed, or commercial building, ensuring you have the right tools and the knowledge to achieve a secure structure is important. Building is a complex process that requires many moving pieces to create one large result. However, when one part of the process is flawed, you could affect the overall project. Below are five common timber framing mistakes to avoid if you want to prevent expensive and unsafe issues.

Forgetting To Check for Crowns

One major timber framing mistake is not checking the studs for crowns, which are small bumps on studs that cause your structure to be uneven or misaligned. Framing requires smooth nailing surfaces, as the panels will bend or warp otherwise. These issues will cause the frame to become unstable and weak over time. An unstable frame can contribute to structural issues that are expensive to combat down the line.

Cutting in the Wrong Places

Having a clear understanding of the structural plan and the steps necessary to make the design come to life is crucial. Small errors and mistakes can result in large integrity issues down the line. Small mistakes, such as hole cutting or notching in improper areas, can reduce the weight a structure can hold. This instability can become a major issue in the future. Ensure everyone is on the same page about the final design so that they can make cuts in the appropriate spots.

Having Inconsistencies in Your Work

When working on the timer framing of your structure, consistency is key to a strong, beautiful building. If you have hard-to-pinpoint inconsistencies, these issues could compromise everyone’s safety. Overdriven fasteners and inconsistent gluing and spacing are common errors in timber framing. Make sure to look over your work and ask questions to your fellow crew members when you need help.

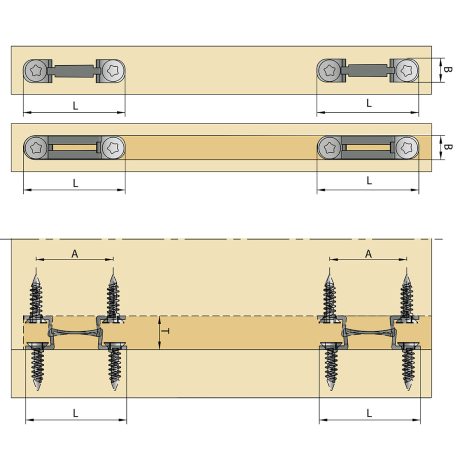

Not Using Structural Connectors

Structural connectors play a major role in your framing process and your building integrity because these connectors reinforce strength and security. If you don’t install these correctly or fail to use them, your build’s frame will weaken, and your structure will be unsafe. Familiarize yourself with your local building codes, and remember to use durable framing connectors.

Not Having Drywall Backing

A common and significant framing mistake to avoid is forgetting to install drywall backing. A lack of backing can greatly affect your work and compromise the safety of the structure’s inhabitants. Drywall backing offers extra support to the building’s wall. Without the backing, the wall is more likely to sag, warp, and break over time. Remember to double-check your work and ensure that you correctly install the drywall backing before moving on to the next step in your building process.

Tips for Perfecting Your Framing

Framing is the skeleton of every structure, and having a strong, durable core will help create a beautiful building. Now that you know the common framing mistakes to avoid, it’s important to know a few tips and tricks to help you perfect your wooden frame. Read on to discover a few things to try when working on a timber frame that will optimize your work.

Stagger Your Seams

Many contractors find that staggering the seams helps create strong bones for your structure. The top and bottom plates have weak points at the seam where two wooden boards join, but staggering can prevent making weak spots in your wall framing. Place the top and bottom plates far away from each other to create a strong structure and eliminate weak points.

A Strong Foundation Is Key

How can you build a structure with a rocky foundation? Before establishing your timber framing, ensure that your foundation and footing are impeccable. You and your crew should be on the same page when discussing where to place anchor bolts and wall plates. Having this conversation will reduce the risk of mistakes and accidents. Use this time to confirm your project adheres to local building codes so that you can prevent delays, major fines, or other consequences.

Use the Right Tools

You must have the appropriate tools to achieve the best results. Contractors achieve such beautiful joinery and beam work because they spend time planning, designing, and ensuring they have the materials and supplies to make it work. Along with basic power tools and wood framing connectors, you need the following:

- Mallet

- Drill press

- Chain mortiser

- Planers

- V-line clamp

- Block plane

- Framing chisel

- Timber framing square

Remember To Store Your Materials Properly

When working with any woodworking materials, it’s essential to store them properly. While most timber framing products can withstand various outdoor conditions, it’s still important that you take care of these products. By properly storing your materials, you can avoid the risk of molding or warping.

All types of wood will expand or contract with changes in air’s moisture content. Keep your wood in good condition by placing the material off the ground and covering it with a waterproof tarp. This way, you can defend it against outdoor conditions.

Build With High-Quality Timber Frame Connectors

At KNAPP Connectors, we believe in building with integrity. Whether you love woodworking as a hobby or are a professional contractor or architect, working with high-quality connectors is key to durable structures. Don’t allow lackluster connectors and fasteners to ruin your beautiful work of art. We offer top-of-the-line beam hangers for timber frames and mass wooden construction.

With an easy snap, our concealed connectors provide maximum strength and prefabrication without demanding much of your time and energy. For over 35 years, we have strived to expand our knowledge and create solutions for self-tightening and concealed woodworking fasteners and connectors. Be sure to browse our website for more information, and don’t hesitate to contact us to answer any questions.