Everything You Should Know About Dovetail Joints

Dovetail joints are a timeless carpentry tradition that woodworkers, hobbyists, and contractors have used for centuries. We’re here to help if you’re new to the craft or want to brush up on your knowledge. Dovetail joinery is a technique known for its strength and intricate design—one that requires skill and patience. Let’s take a deeper dive into what makes these joints so special to understand this beloved connector better. We’ll explore their history, construction techniques, tools needed, and tips for getting perfect results every time. Read on to discover everything you need to know about dovetail joints!

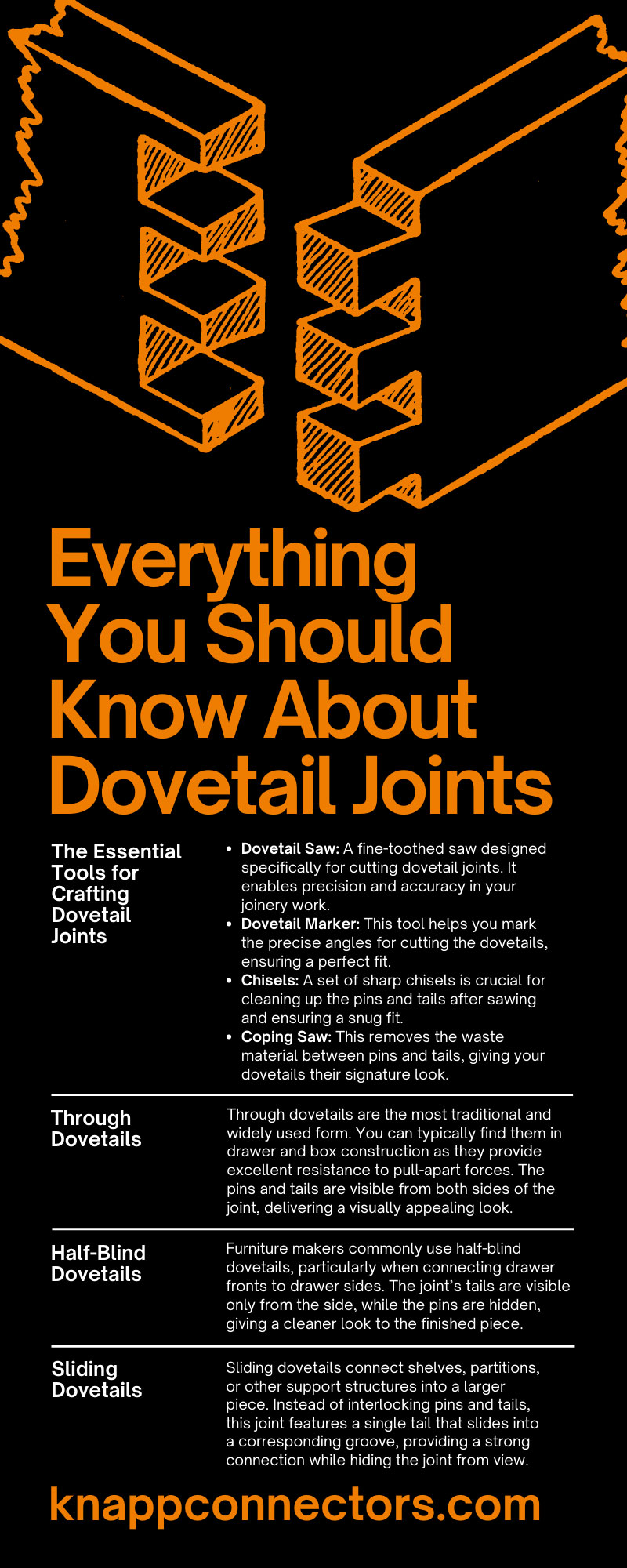

The Essential Tools for Crafting Dovetail Joints

Dovetail joints are a fundamental part of woodworking and require specific tools for optimal results. Here are four essential tools to have in your arsenal:

- Dovetail Saw: A fine-toothed saw designed specifically for cutting dovetail joints. It enables precision and accuracy in your joinery work.

- Dovetail Marker: This tool helps you mark the precise angles for cutting the dovetails, ensuring a perfect fit.

- Chisels: A set of sharp chisels is crucial for cleaning up the pins and tails after sawing and ensuring a snug fit.

- Coping Saw: This removes the waste material between pins and tails, giving your dovetails their signature look.

With these tools, you can create beautiful and sturdy dovetail joints.

The Different Types of Dovetail Joints

Dovetail joints are a true marvel in woodworking. Each style serves a unique purpose, adding aesthetic appeal and structural strength to your projects. Let’s explore three common types that you should consider incorporating in your woodworking endeavors.

Through Dovetails

Through dovetails are the most traditional and widely used form. You can typically find them in drawer and box construction as they provide excellent resistance to pull-apart forces. The pins and tails are visible from both sides of the joint, delivering a visually appealing look.

Half-Blind Dovetails

Furniture makers commonly use half-blind dovetails, particularly when connecting drawer fronts to drawer sides. The joint’s tails are visible only from the side, while the pins are hidden, giving a cleaner look to the finished piece.

Sliding Dovetails

Sliding dovetails connect shelves, partitions, or other support structures into a larger piece. Instead of interlocking pins and tails, this joint features a single tail that slides into a corresponding groove, providing a strong connection while hiding the joint from view.

The Pros and Cons of Using Dovetail Joints

Dovetail joints are no exception when it comes to joinery techniques. These timeless joints offer a range of advantages and disadvantages that can greatly impact your woodworking projects. Considering the pros and cons of dovetail joints is crucial when making informed decisions for your projects, whether you’re an experienced woodworker or a beginner looking to expand your skills.

Pros:

- Exceptional strength and durability.

- Visually appealing, adding value to your furniture.

- Less reliance on adhesive or fasteners.

- A time-tested and proven method for creating long-lasting pieces.

Cons:

- Can be time-consuming and requires practice to perfect.

- Requires specialized tools for optimal results.

- May not suit some modern minimalist designs.

A World of Applications: What Can You Use Dovetail Joints For?

Dovetail joints have a wide range of applications in woodworking and furniture making. Some common uses include:

- Drawer and Box Construction: The interlocking pins and tails provide a sturdy and durable connection, ideal for withstanding the stresses of opening and closing drawers or boxes.

- Tabletops and Shelving Units: The sliding dovetail joint is an excellent choice for connecting shelves or attaching a tabletop to its base. It provides a strong bond while hiding the joint from view.

- Cabinet and Furniture Assembly: Dovetail joints’ strength and aesthetic appeal make them a popular choice for connecting various parts of furniture, such as case sides and shelves.

- Joinery Reinforcement: You can use dovetail joints to reinforce weaker joinery methods, such as butt or rabbet joints, providing added strength and durability.

How To Achieve Precise Dovetail Joints

Creating precise dovetail joints can be a rewarding yet challenging task, especially for beginners. However, with a few helpful tips and a sprinkle of patience, you can master the art of cutting flawless dovetails and take your woodworking skills to the next level.

Practice Makes Perfect

As with any woodworking skill, practice makes perfect. Start by honing your technique on scrap wood before moving on to your actual project. Embrace the learning process and the mistakes as valuable lessons.

Keep Your Tools in Great Shape

The quality of your tools will influence your piece’s final look and durability. The importance of sharp tools is one aspect to keep in mind. Dull chisels and saws can lead to inaccurate cuts and a poor fit. Ensure you maintain your tools well and regularly sharpen them to achieve precise and clean cuts.

Measure Twice, Cut Once

A timeless mantra in the world of woodworking. Before making any cuts, ensure your measurements are accurate. Remember, precision is key when it comes to dovetail joints. Take the time to triple-check your measurements before committing to the cut.

Before you reach for the glue, do a test fit. Always ensure that the joint fits snugly before applying any adhesive. Gently trim the joint for a perfect match if it’s too tight. Conversely, don’t hesitate to start over and make the necessary adjustments if it’s too loose.

Make Sure To Take Your Time

Your precious ally in crafting perfect dovetail joints is time. Don’t rush the process. Take your time when marking, cutting, and fitting the joints together. Enjoy the rhythm of the woodworking journey and savor every step toward a beautifully crafted piece.

Think About Your Material Choice

The choice of wood can greatly enhance the overall aesthetic of your dovetail joints. Opting for high-quality wood will make your work easier and produce beautifully intricate joints. Softwoods like pine are easier to cut, while hardwoods like oak or walnut offer durability and a refined finish.

Dovetail joints may require some practice and specialized tools, but their strength, beauty, and versatility make them a valuable furniture-making technique. You can build with integrity now that you know everything you need to know about dovetail joints. Incorporating dovetail joints into your projects can elevate the quality and value of your work, whether you’re a professional manufacturer or a hobbyist woodworker. At Knapp, we offer high-quality concealed woodworking joints, like carpentry connectors, to help you along the way. Browse our website and contact us today for more information.