Every craft trade requires a skill set that can transform your work from ordinary to astounding. For painters, it’s how you hold the brush and your painting techniques; for sculptors, it’s how you carve and assemble your sculpture; for woodworkers, it’s joinery.

Wood is one of the most versatile materials used in construction and crafting. For thousands of years, wood has been used for homes, boats, tools, and furniture, making it a huge part of civilization, humanity, and how we perceive this material.

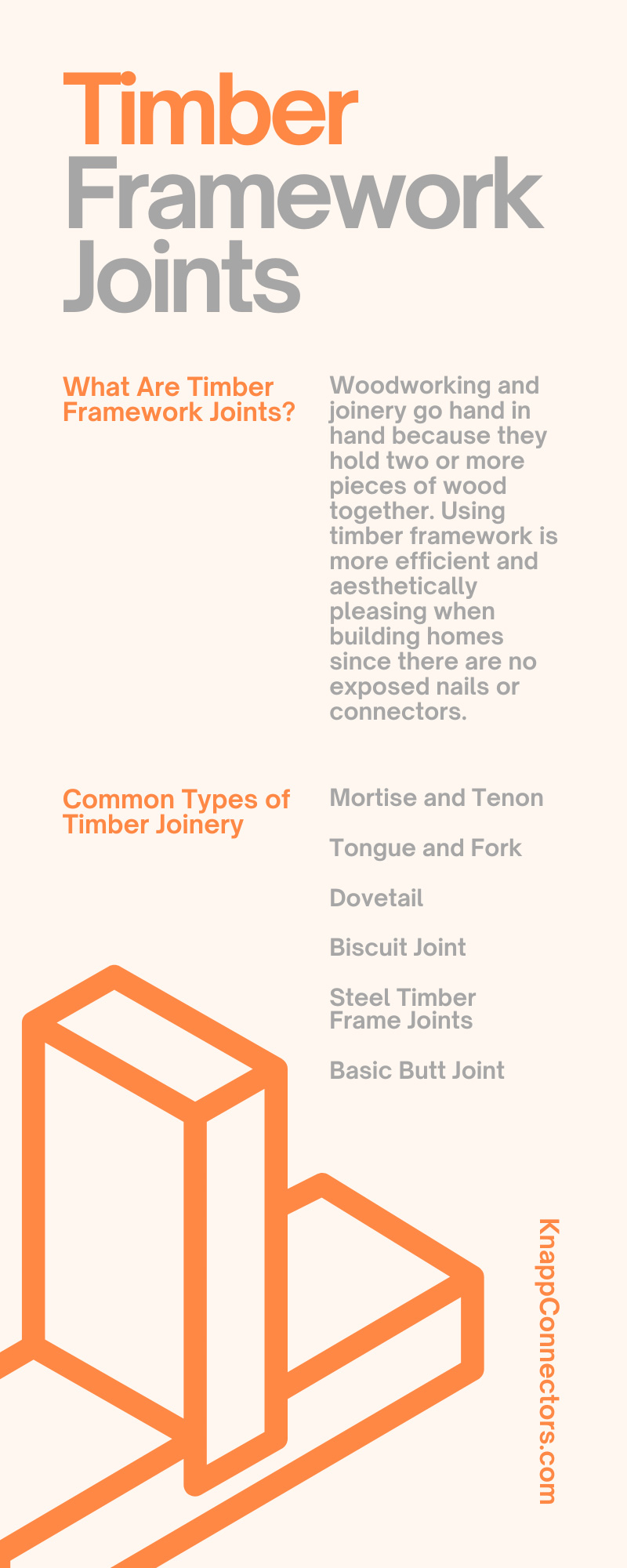

Wood joinery is one of the most basic but complex concepts in woodworking. Joinery allows you to combine two pieces of wood instead of carving out a table or sculpture. However, there are many wood joints, depending on the project. To help master the concept of wood joinery, here’s our comparative guide to timber framework joints.

What Are Timber Framework Joints?

Woodworking and joinery go hand in hand because they hold two or more pieces of wood together. Using timber framework is more efficient and aesthetically pleasing when building homes since there are no exposed nails or connectors.

Timber framing isn’t a new concept. Timber framing is found in some of humanity’s first structures and castles, homes, churches, and manors and stands tall today. Timber framework joints can be simple or complex, but the element that defines these joints is the strength and integrity that holds the beams in place.

Carpentry vs. Joinery

As we mentioned, wood is one of the most versatile materials to use in construction and crafting, and working with wood requires a certain type of mastery and craftsmanship. Carpentry and joinery are the two main trades that handle wood and demand high skill sets in construction and architecture.

However, these two trades have their differences. A carpenter has specialized skills in assembling wood fixtures like doors, windows, formwork, and stud work. You rarely see carpenters manufacturing objects that aren’t involved in the daily routine of construction sites. However, joiners are masters at producing items like furniture or decorative home items and typically work in a workshop.

Hand Tools You Need for Timber Joinery

Before you can admire your intricate joinery work, it’s always best to know which hand tools you need to master your skills. Although it’s easier to use the tools you may already have, here are a few hand tools you need to achieve extraordinary woodwork.

Framing Chisel

A framing chisel is a hand tool that can help make shaping or cutting easier. This tool will help round out the edges of your wood or cut off a tiny piece of wood. This tool can be used by hand or with a mallet to help get a precise cut.

Mallet

Chisels and mallets are like peanut butter and jelly—they go hand in hand. When using a mallet for woodworking, you don’t want your mallet to be too heavy or too light to prevent incidents or broken wood. Look for a well-balanced mallet to minimize the impact of the chisel coming down.

Hand Saw

Hand saws come in many variations for different projects and can cut any wood. The type of hand saw you use solely depends on personal preference. For example, some people prefer a western-style hand saw that cuts as you push, while others prefer a Japanese hand saw that cuts as you pull.

Framing Square

Also known as a carpenter’s square, a framing square is essential for measuring and marking angles when working with wood. This L-shaped tool creates a perfect 90-degree angle that can act as a ruler to help you indicate accurate measurements and ensure your wood fits perfectly.

Common Types of Timber Joinery

Now that we’ve gone over the basics of woodworking, carpentry, and the purpose of timber framework joints, we can finally go over the traditional joints used in timber framing. Timber framing connects wood using only wooden parts, which makes it more aesthetically pleasing using a method that utilizes exposed nails, bolts, and other connectors. Here’s our comparative guide to different types of timber framework joints.

Mortise and Tenon

Mortise and tenon are the strongest and most common types of timber joinery. These joints have been used since the beginning of woodworking and are still found in older structures. A mortise and tenon are formed so the tenon, or tongue, fits perfectly into the pocket or mortise.

Tongue and Fork

The bridle joint, or the tongue and fork, is like the mortise and tenon. However, this type of joinery is often used to connect rafters together due to its strength and durability. The tongue and fork joints are less aesthetically pleasing than the other joints because the end of the tenon is visible.

Dovetail

Dovetail is the “old-school” way of combining two or more pieces of wood. This technique has been found in the tombs of ancient Egyptian and Chinese emperors. The dovetail flare interlocks the two wooden pieces and prevents them from coming apart. Although it’s beautiful, it’s hidden in the finished building.

Biscuit Joint

Another joinery method used in woodworking and construction is the biscuit joint. This joint connects boards along the edges using the clots and beechwood wafter to secure them. This joinery is common in modern woodwork or modern-styled furniture, like tables or desks.

Steel Timber Frame Joints

For those who want to achieve a “vintage” or “old-school” factory look, steel timber frame joints are your best choice. These joints offer an enormous amount of support, allowing you to use heavier wood over a larger span. You can also customize your steel plates to fit the project requirements and aesthetics.

Basic Butt Joint

There’s nothing simpler in joinery than the butt joint. Although it has a funny name, this joint can help save a lot of time and money when building your structure. This joint is nothing more than fitting one piece of wood into another, often in a square shape or angle. These joints are often used to frame the wall on construction sites.

There are many different types of framework joints and carpentry connectors that can help you get the job done. We have connectors for any industry, from furniture manufacturing to staircase manufacturing to window and door manufacturing. Whatever you need, Knapp is here to help! Don’t hesitate to contact us if you have any questions.