The key to upgrading your woodworking skills is to know which wooden joints and fasteners are best for your projects. Expanding your knowledge about wood joints and when to use them is a great skill to have and ensures your work is secure and ready for use. The number of creative ideas you can bring to life is endless when you are familiar with different wood joint types.

While this skill may seem basic, no matter how many projects you’ve made, everyone could use a refresher occasionally. There are various ways to combine pieces of wood, and each joint has a different purpose.

We encourage our readers and woodworking enthusiasts to educate themselves on the various types of wood joints and when to use them appropriately. By doing so, you can create flawless projects with excellent joinery skills. Keep reading to discover all the ways you can join your wooden pieces.

What’s the Best Wooden Joint To Use?

It’s easier to know which wooden joint to use when you understand the different types of wooden joints and their intended uses. Although a beginner knows not to use a dovetail joint for floorboards or rabbet joints for beds, it’s always great to have a review.

Finding the perfect wooden joint comes from a process of elimination. It may take a few trials and errors, but that’s why we’re here! You choose the best joint for your project by evaluating its complexity, functionality, and strength.

While some projects call for lower levels of reinforcement, others may require stronger and more durable joinery. It’s important to go into the project knowing that each type of wooden joinery has a specific purpose.

The Best Uses for Wooden Joints

Why would you need to use wooden joints in the first place? Wood joints have various uses, depending on the context in which you employ them. Some joints have specific purposes, while others are universal. You can use these joints for furniture making, decorative art, cabinetry, and other construction projects, like decks and patios.

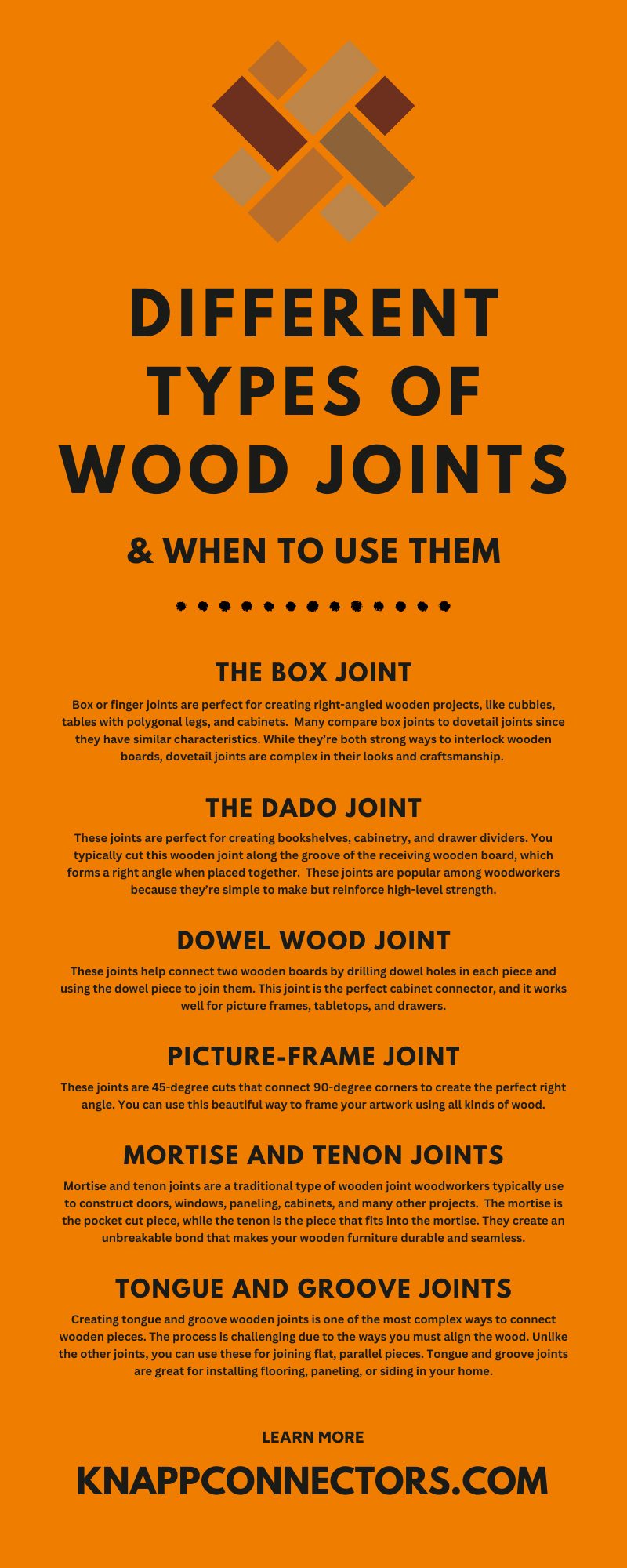

The Box Joint

Box or finger joints are perfect for creating right-angled wooden projects, like cubbies, tables with polygonal legs, and cabinets. You can create these joints by carving out notches in your wooden boards so they interlock simultaneously. Since you’re joining them at a 90-degree angle, their hold is so strong that you need little adhesive.

Many compare box joints to dovetail joints since they have similar characteristics. While they’re both strong ways to interlock wooden boards, dovetail joints are complex in their looks and craftsmanship. Box joints are a great way for beginner woodworkers to explore different techniques.

Creating box joints is a traditional woodworking method, and you can create most joints with a saw or knife. However, you can use an electric saw for a more efficient cut and alignment.

The Dado Joint

Dado joints are one of the simplest joints to create and are great for beginning woodworkers to try. These joints are perfect for creating bookshelves, cabinetry, and drawer dividers. You typically cut this wooden joint along the groove of the receiving wooden board, which forms a right angle when placed together.

These joints are popular among woodworkers because they’re simple to make but reinforce high-level strength. If you want additional security, we recommend using a wood adhesive.

Dowel Wood Joint

Dowel joints are one of the most durable self-holding connectors to use for woodworking projects. These joints help connect two wooden boards by drilling dowel holes in each piece and using the dowel piece to join them. This joint is the perfect cabinet connector, and it works well for picture frames, tabletops, and drawers.

While traditional wooden dowels require gluing and clamping, we provide metal and plastic dowels that can withstand wear and tear. Our cutting-edge technology helps reduce the time and labor used to connect wooden pieces. Dowel joints also provide an aesthetically pleasing finish because you can hide the connectors within the wood.

Picture-Frame Joint

Picture-frame or Miter joints can be challenging to execute without the appropriate tools and experience. These joints are 45-degree cuts that connect 90-degree corners to create the perfect right angle. You can use this beautiful way to frame your artwork using all kinds of wood.

It is best if you equip yourself with biscuit joints to connect the pieces of wood. Create slots between your two pieces of wood to establish a seamless look. Then, glue the biscuits inside to craft a flawless finish and strong hold.

Mortise and Tenon Joints

Mortise and tenon joints are a traditional type of wooden joint woodworkers typically use to construct doors, windows, paneling, cabinets, and many other projects. These joints are essential to woodworking skills but may take time to learn. The mortise is the pocket cut piece, while the tenon is the piece that fits into the mortise. They create an unbreakable bond that makes your wooden furniture durable and seamless.

Tongue and Groove Joints

Creating tongue and groove wooden joints is one of the most complex ways to connect wooden pieces. The process is challenging due to the ways you must align the wood. Unlike the other joints, you can use these for joining flat, parallel pieces. Tongue and groove joints are great for installing flooring, paneling, or siding in your home. Many use these joints for engineered wood or laminate flooring.

We hope our guide on the different types of wooden joints and the best time to use them sparked your imagination and inspired you to work on many wooden projects. Our goal is to ensure that your projects are durable and long-lasting. At Knapp, we strive to innovate the woodworking industry and cut down on labor costs and energy.

Like us, you love bringing your designs to life and believe it shouldn’t take all day. We also believe that a seamless finish is a flawless finish. At Knapp, we have the connectors, whether you’re creating picture frames, coffee tables, or framing for your outdoor projects. Check out our website for more information, and browse our store for all your connecting needs.