Though windows are best known for the beautiful views they provide, they’re also integral to the structural integrity and aesthetics of a building. Whether you’re a construction expert or a seasoned woodworker, long-lasting, stable windows should be a goal for professionals like you. While you’ve probably already got an arsenal of techniques and tools, one innovation deserves a closer look—hidden fasteners.

Explore how to improve window stability with hidden fasteners, and learn why they’re superior to traditional fasteners. Plus, you’ll get some tips on how you can integrate them into your workflow seamlessly.

Why Hidden Fasteners Are Game-Changers

Aesthetic Meets Functionality

Your clients want windows that are not only secure but also stylish. Traditional fasteners can create visual disruptions, standing out in ways they don’t want.

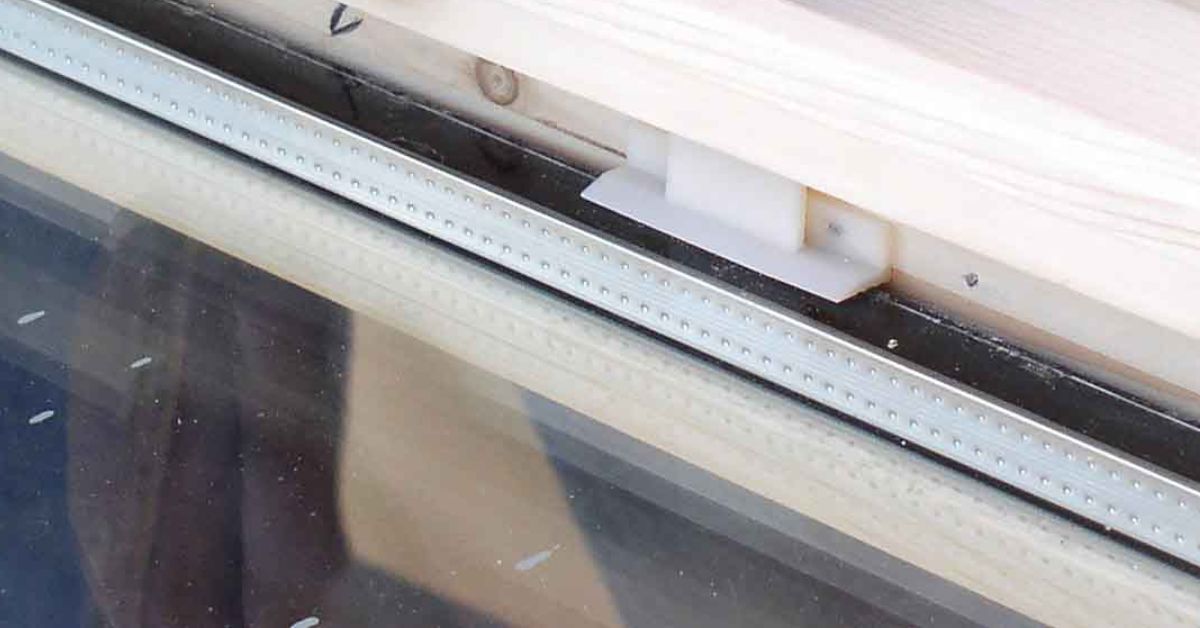

Luckily, hidden fasteners are window manufacturing connectors that deliver clean, unobstructed lines to showcase the woodwork or windowpane—not the hardware. This subtle yet powerful touch helps you achieve a polished, seamless finish that wows clients.

Enhanced Durability and Stability

Unlike visible nails and screws, hidden fasteners evenly distribute stress and pressure across a window frame. By reducing the risk of the material weakening, splitting, or warping over time, these fasteners create a more robust, long-lasting structure.

Whether your window is battling seasonal temperature swings or heavy winds, hidden fasteners provide a level of stability that conventional methods often struggle to match.

No Compromises on Strength

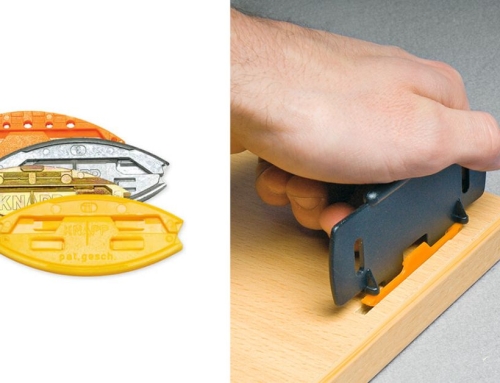

Don’t be fooled by the word “hidden”—just because you can’t see them doesn’t mean they’re less effective. With precision-engineered materials such as aluminum and stainless steel, hidden fasteners are specially designed to hold components with a firm and secure grip while keeping elegance intact.

Are you new to the world of hidden fasteners? Make sure to start with mid-sized or standard windows. These allow you to practice balancing aesthetics and strength without becoming overwhelmed with the complexity of more intricate projects.

Types of Hidden Fasteners for Windows

To choose the right hidden fastener, you must know what’s in your toolkit. Discover some of the most common solutions and their key applications.

1. Concealed Clips

These little wonders snap invisibly behind window profiles, locking securely into place. They’re perfect for lightweight and medium-duty installations, where aesthetics are the driving factor.

As a bonus, concealed clips are incredibly easy and quick to install. If you have frames made of wood, aluminum, or PVC, these fasteners are your best bet. For example, concealed clips work great for sliding patio windows or decorative wooden casements.

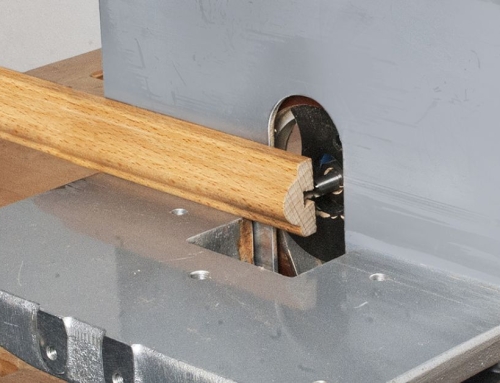

2. Spline Fasteners

Spline fasteners use interlocking grooves to attach frames tightly together without visible screws. With their excellent load-bearing capacity, ability to minimize stress distribution across the frame, and sheer-force resistance, spline fasteners work best on heavier-duty applications.

Consider using these fasteners for large windows that are fixed in place, usually found in office buildings, showrooms, or other big areas.

3. Hidden Brackets

These are mounted inside precut grooves of the frame, virtually disappearing after installation. Hidden brackets work well for complex, high-performance glass systems requiring extra structural support.

Their enhanced flexibility allows for custom shapes and designs, and they are effective for both wood and metal-framed windows. Installing windows on a high-end storefront or luxury residential home? Hidden brackets are the fasteners for you. To avoid accelerated corrosion, always check compatibility between your chosen fasteners and the materials you’re working with.

Installation Made Easy

It’s no secret that great execution starts with technique. While hidden fasteners may seem intimidating to integrate into your workflow, following these steps will help you nail the process with precision and confidence.

1. Prepare the Frame

Start with a perfectly measured and square-cut window frame—accuracy in this step impacts everything down the line.

Create designated grooves or slots based on your chosen fastener type, ensuring they align properly. Remember—a misplaced millimeter now can cause wobbling and weaken stability later. To prevent unforeseen alignment issues, use precise measuring instruments like laser levels or calipers.

2. Choose the Right Tools

Each fastener has specific requirements. For example, concealed clips often need specialized clip-fastening tools, while spline systems may call for interlocking press kits. Good tools do half the job for you, so pick wisely.

3. Secure the Fastener

Position your hidden fastener carefully within the frame groove or slot and secure it into place. Ensure they fit tightly, avoiding over-torquing screws, as this may damage your material.

For extra adhesion, apply a small amount of wood adhesive along spline fasteners—just be sure to clean any excess immediately for a flawless finish.

4. Test and Assess Stability

Once your fasteners are in place, test the window’s stability by applying pressure along various points of the frame to assess rigidity. If there’s a flex or wobble, adjust the fasteners immediately before the final installation.

Why Professionals Like You Are Making the Switch

You’re meticulous in your craft and understand the need for innovation, so hidden fasteners align perfectly with your desire to combine advanced techniques with inspired design.

But beyond functionality, adopting hidden fasteners signals your commitment to modern construction methods that honor both form and function. When working with clients, windows free of visible screws or nails communicate precision workmanship in every detail—a key selling point when bidding for high-end projects.

Addressing Common Concerns

“Aren’t Hidden Fasteners More Expensive?”

While the upfront cost may be slightly higher, hidden fasteners can lower lifetime costs by reducing maintenance and replacement needs. Their durable design minimizes wear and ensures your installations stand the test of time.

If your clients are concerned about the upfront price, educate them about long-term savings, and they’ll quickly see the value.

“What About Accessibility for Repairs?”

High-quality hidden fasteners are thoughtfully designed with future repairs in mind. Many use modular setups, allowing for the replacement of individual components without compromising the entire structure.

“Will My Team Need Extra Training?”

Any additional training should be minimal. If your team already uses standard fastening methods, hidden fasteners are an easy upgrade. Plus, many brands provide installation guides or offer hands-on demos, making the learning curve manageable.

To get your team up to speed in a low-pressure environment, consider hosting an educational workshop.

Looking Ahead

Say goodbye to clunky, over-engineered setups and hello to streamlined perfection. Now that you know how to improve window stability with hidden fasteners, you can elevate your craft, impress your clients, and guarantee that the structures you create marry durability with beautiful design.

Hidden fasteners are a worthy addition to any professional toolkit. To integrate them into your work, explore the hidden fasteners available at Knapp connectors.