Mod-eez®️ Single Clip Connectors

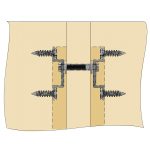

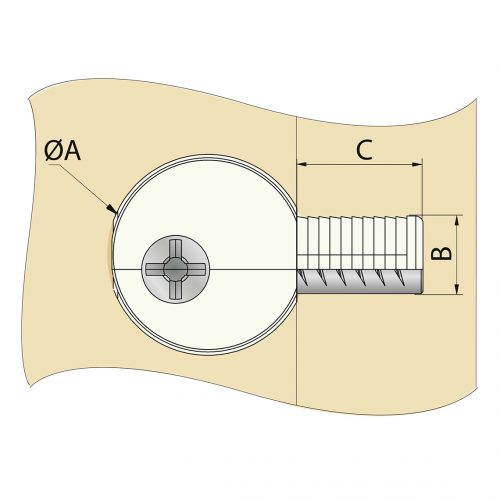

The Mod-eez®️ system was developed to join panels securely together in a fast and simple method with no visibility of the connector. The Mod-eez®️ Fastening System meets the objective by utilizing a spring steel declining ramp “clip” and a large collared Shoulder Screw at the two mating members. Spring steel makes the joint strong, yet flexible, while the collar on the Shoulder Screw adds tremendous resistance to torsional pull-out. Assembly occurs by simply sliding the Shoulder Screw head down the clips ramp. With the clip located in its pocket, and the system assembled, all fasteners disappear.

Mod-eez®️ come in Single Clips, Double Clips, and Anti-Rotation Clips and with each, there are 4 types available: Pass-thru, non-locking (easy to disassemble), semi-locking (hard to disassemble), and locking (cannot be disassembled). Mod-eez®️ comes in two widths, working with both 5/8″ and 3/4″ + material.

Mod-eez Sets are also available, which include the Clip, Shoulder head screw, and mounting screws.

Features and Benefits:

- Fast assembly

- Efficient and very good to use in production line manufacturing.

- Components are simply hooked together in seconds

- Reduces labor and equipment cost

- Efficient: High degree of pre-manufacturing.

- Components can be transported and simply assembled on site.

- Non-visible connector

- Appeals to the architect and customer

- Concealed

- Self-tightening

- The pass-thru, non-locking and semi-locking clips can be disassembled and reassembled

- Versatile

- For materials from 16 mm thickness and up.

- Used with all solid and wood-based materials and plastic as well as steel and aluminum.

- 4 types of clips: Pass-thru, non-locking, semi-locking, and locking.

- Durable and Strong

- Spring steel sturdy design

- Longer PH-screws (approx. 5 x 60), can significantly increase the strength of the connector.

Tips:

- Perfect for industrial manufacturing with CNC

- Welding Mod-eez®️ Clips to steel (i.e. approximately 16 ga.) can be accomplished by wire welding.

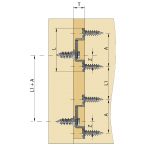

- Pockets to receive connectors are normally routed into the edge of a panel but can be routed into the face when design so requires.

- To prevent engaged members from rotating (without anti-rotation clips) attach the Shoulder Screw in the pocket and the clip on the surface.

- For handheld routers, use our Mod-eez®️ Drilling and Depth Jig for a perfect installation every time.

- Used with all wood and board materials

Applications:

- Case Goods

- Cabinets

- Chairs

- Furniture

- Interior design

- Shop fittings

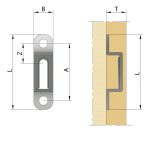

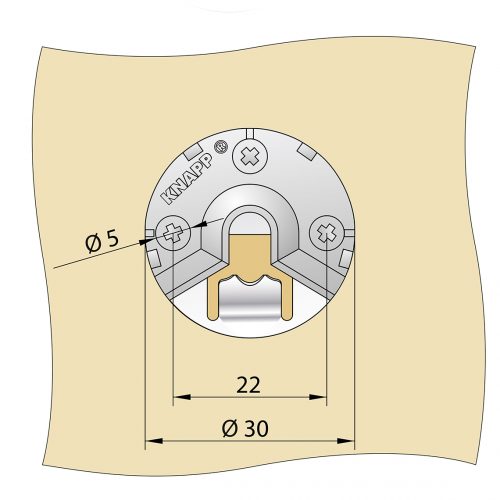

Mounting

With PH- or CS-screws Ø = 4,5 mm (length as required).

Advantages

Concealed, self-tightening connector for 32 mm system, demountable, for timber and steel.

Installation

Spindle moulder, plunge router, CNC equipment.

Suitable materials:

For all solid wood, wood-based panels and plastic materials from 16 mm thickness up.

Application

Case goods, shop fittings, furniture