The Dowel Starter Kit contains a variety of RTA dowels that will have you well on your way to building furniture, cabinets, and case goods. Choose from 2 different packs!

Dowel Starter Kit – Variety Pack

$69.00 – $119.00

Out of stock

Description

2 Dowel Starter Kits to choose from!

Dowel Starter Kit Classic

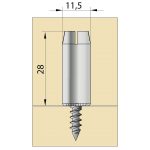

- 30x KNAPP-Dowel 6×28 mm

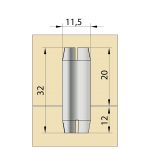

- 30x KNAPP-Dowel 8×36 mm

- 30x TUCK 6/28 mm

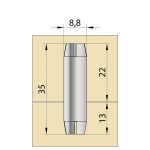

- 30x TUCK 8/35 mm

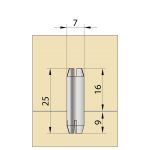

- 30x QUICK-SET 5/11 mm

- 30x QUICK-SET 8/8 mm

- 1x KNAPP Adhesive PU+

Dowel Starter Kit +

- 30x KNAPP-Dowel 6 mm

- 30x KNAPP-Dowel 8 mm

- 30x TUCK 6/25 mm

- 30x TUCK 8/35 mm

- 30x TUCK 10/32 mm

- 30x TUCK 10/28 mm

- 30x TUCK 10/16 mm

- 30x QUICK-SET 5/7.5 mm

- 30x QUICK-SET 5/11 mm

- 30x QUICK-SET 8/8 mm

- 30x QUICK-SET 8/26 mm

- 1x KNAPP Adhesive PU+

KNAPP Adhesive PU+ Included!

- Our KNAPP Adhesive PU+ is a strong and durable one-component polyurethane adhesive that bonds virtually everything.

- This can be used with the KNAPP-Dowel as well as the TUCK Spring Steel Compression Dowel.

Applications

Case Goods and Furniture

Windows and Doors

QUICK-SET Dowel

Videos

KNAPP-Dowel

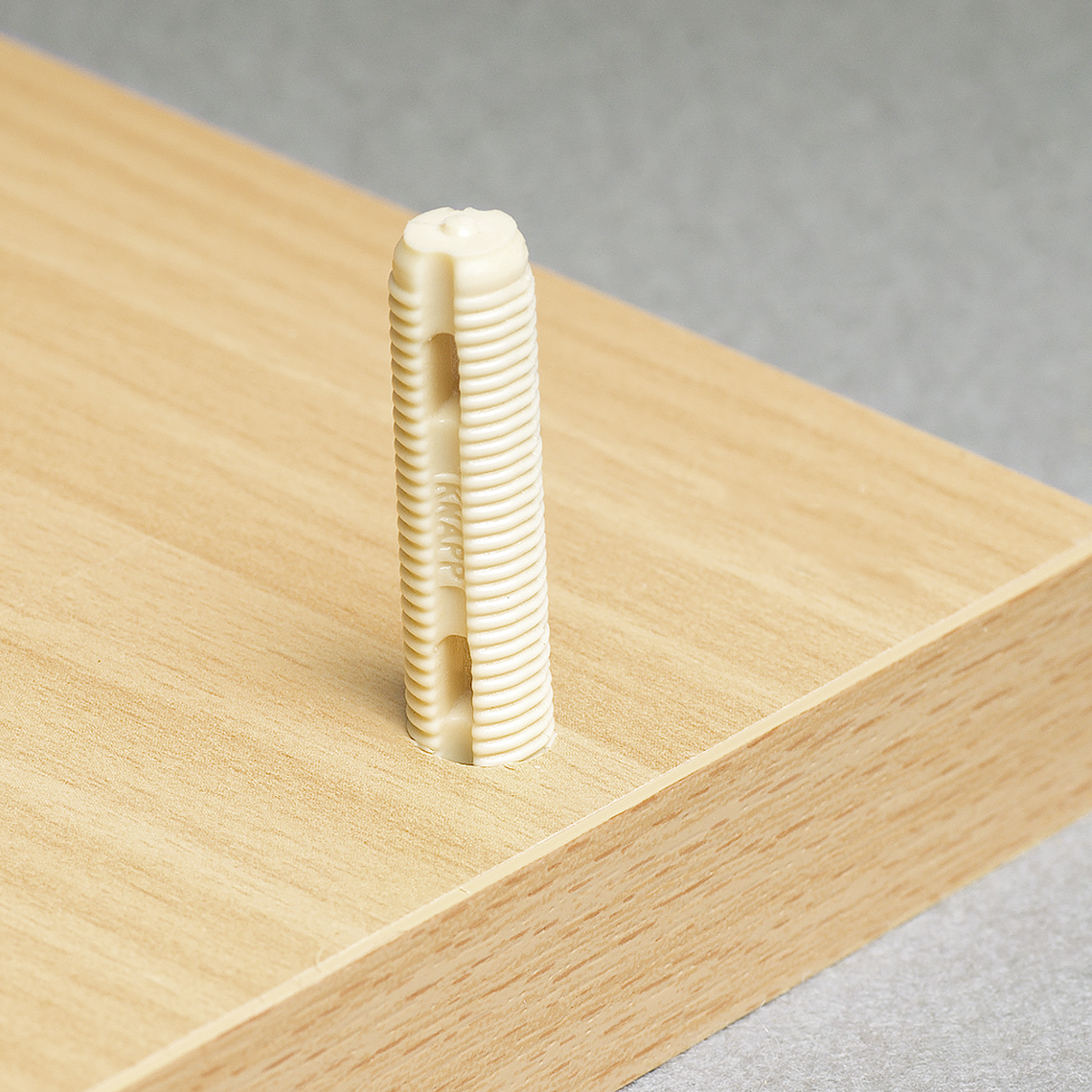

KNAPP®-Dowel self-tightening plastic dowel

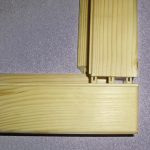

The KNAPP®-Dowel is a strong and durable self-holding plastic dowel connector available in 6x28 mm and 8x36 mm. Consists of high-strength weather-resistant (POM) plastic and gripping itself into the borehole due to its special design of threaded ribs and lengthwise groove, hence, no clamping of the workpiece needed. Unlike conventional wooden dowels, it has the option to be used with or without adhesive.

Features and Benefits:

- Design – the threaded ribs, lengthwise groove, and holes on both ends ensure:

- a strong anchoring in the material, hence depending on the applications and conditions it can be used with or without adhesive.

- optimal distribution of adhesive and prevent bulging of i.e. chipboards due to the swelling of wooden dowel.

- fast manufacturing as there is no clamping needed and immediately load-bearing → especially beneficial for an automated manufacturing process.

- Material – high-quality polyacetal (POM) plastic, thus no shrinking and swelling

- no opening of the joint due to shrinkage and swelling behavior, even when exposed to the environmental humidity changes.

- weather resistant, thus suitable for outside applications.

- guaranteed quality no risk of breakage and cracking with our dowel connector, as opposed to hardwood dowels (beech dowels, etc.)

- does not rot as opposed to wooden dowels

Tips:

- KNAPP®-Dowels work very well for dowel machines, and therefore, we recommend simple white glue (for example PVAc) for easy and simple cleaning of the machines.

- Not recommended to combine with wooden dowels

- Recommended to use with KNAPP®-Adhesive PU+ (Z011/1)

- The KNAPP-Dowel can be processed within 7-10 minutes when using KNAPP-Adhesive PU+

Applications:

- Case goods and architectural millwork for any material where normal dowels are used

- Suited for outside use

- Windows and doors

- Especially popular for millwork on boats and areas of high humidity → due to it being lighter than a wooden dowel.

Polyacetal (POM) - weather-resistant plastic dowel.

Knock-in, optionally gluing with KNAPP®-ADHESIVE PU+.

UV-resistant, self-tightening dowel.

Doweling jig, doweling joiner, automatic dowel insertion machine.

All kinds of wood materials (solid and composite materials).

Case goods, cabinets, furniture, windows, shopfitting.

KNAPP®-ADHESIVE PU+ | Art.-No. Z011

TUCK

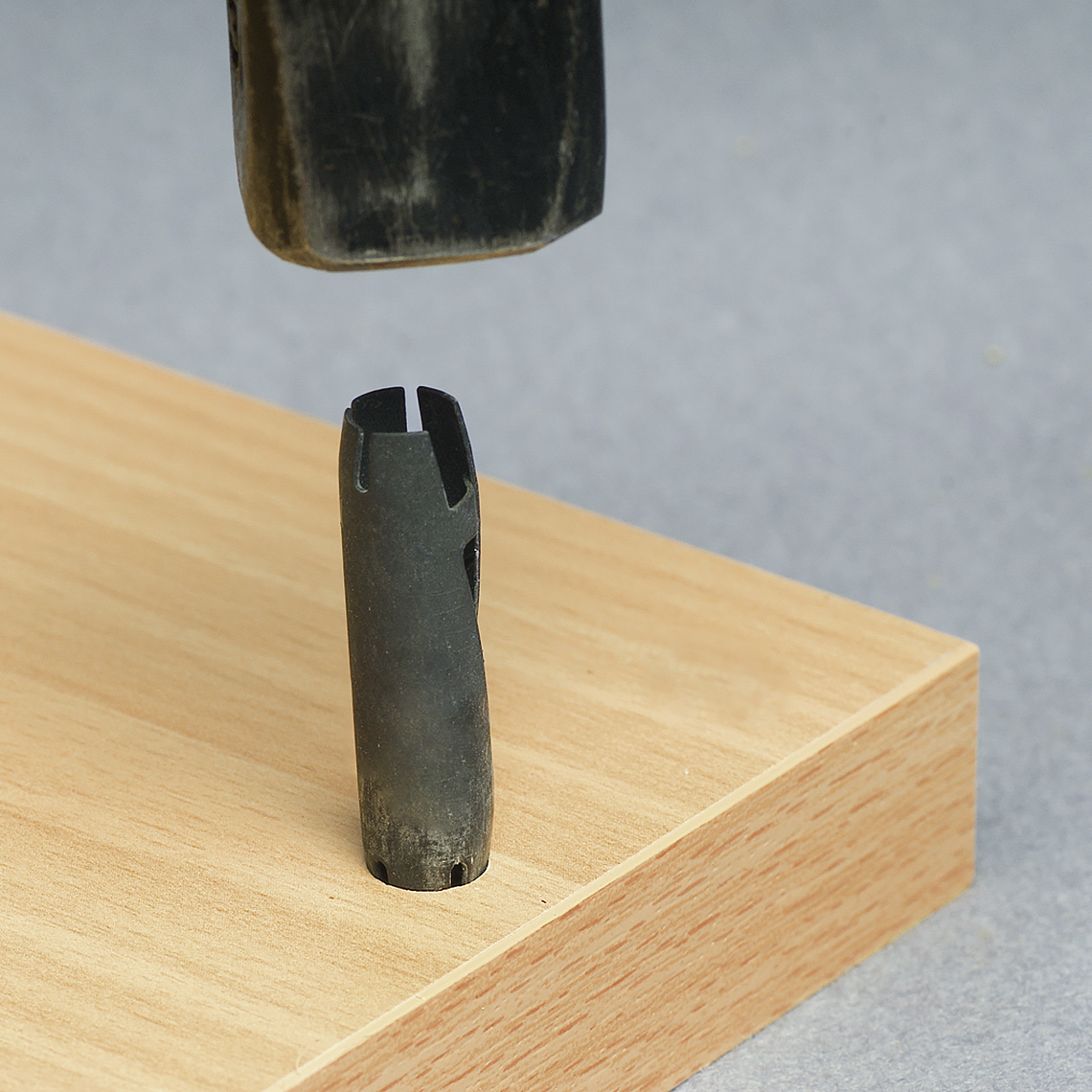

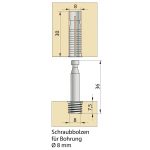

TUCK - Spring Steel Compression Dowel

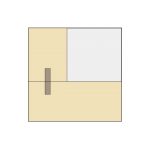

The TUCK is a spring steel compression dowel that is immediately load-bearing for attaching components without glue or clamps. The TUCK is self-tightening and no clamping aid or glue is required when assembling the workpiece (cabinet, furniture, interior design, etc.). The spring steel design guarantees permanent tightening by pushing against the borehole wall. The processing can be done with a dowel-boring machine or CNC.

Available in 5 Sizes

- Processed like a conventional wooden dowel

- Ø 6 mm x 25 mm

- Ø 8 mm x 35 mm

- Ø 10 mm x 32 mm

- Screwed on one end and knocked into the borehole

- Ø 10 mm x 28 mm

- Ø 10 mm x 16 mm

Features and Benefits:

- Fast assembly

- Components simply snap-in and join together in a second.

- Reduces labor and equipment cost

- Non-visible connector

- Appeals to the architect and customer

- Self-tightening

- no need to clamp the workpiece during assembly

- snaps straight in and is used where design or space conditions do not allow the usual sliding connection

- Gluing aid

- Very popular to use as a gluing aid

Tips:

- Works great for RTA furniture.

- Used with all wood and board materials (solid and composite materials)

- Recommended glue for a permanent joint → KNAPP®-Adhesive PU+ (Z011/1) or to install with the connector for reinforcement

Applications:

- Case Goods

- Architectural Millwork

- Shop fittings

- Furniture

- Gluing aid

- Moldings and trim

- Face frames

- False fronts

Spring steel - black

none

Dowel, spring steel

Self-tightening by the tension power against the borehole

Concealed, self-tightening dowel, for immediate use without waiting time

Doweling-jig, cordless drill, dowel inserting machine

All kind of wood materials (solid and composite materials)

Furniture, cabinetry, case goods, shop fittings

QUICK-SET

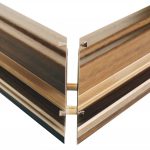

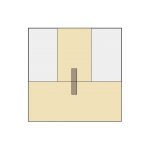

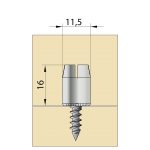

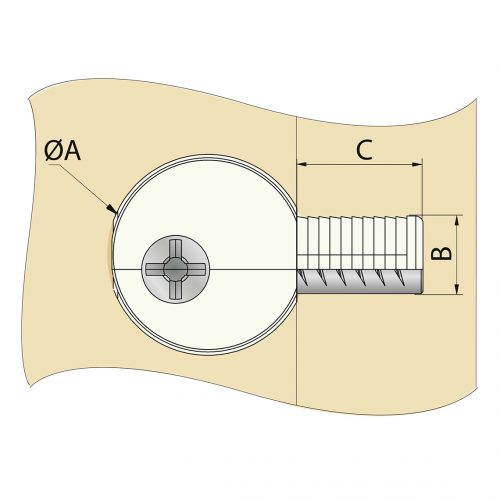

QUICK-SET - 2 Part Locking Dowel

The QUICK-SET is a simple and efficient 2-part Locking Dowel connector including a threaded stud and a plastic sleeve. The QUICK-SET is self-tightening, non-visible, and can be inserted immediately into standard boreholes without waiting for glue to dry. Cabinets and case goods can be put together on-site quickly and easily, thus high transport costs are omitted. The processing of the two-piece connector is the same as with a conventional dowel - but in a much shorter time. In addition to its main area of application as a modern case goods connector, the QUICK-SET can also be used for drawers.

Features and Benefits:

- Fast assembly

- Components are simply snapped together in seconds

- Reduces labor and equipment cost i.e. no puttying of nail holes, breaking of trim through nailing

- Saves production and assembly time

- No Gluing - Due to the gear wheel embossing on the outside of the plastic dowel and anchoring to the dowel bottom (bolt), the QUICK-SET does not require any adhesive during application.

- Non-visible connector

- Appeals to the architect and customer

- Self-tightening

- No clamping necessary

- Pulls itself tighter once

- The connection is permanent and cannot be disassembled

- Safe and Strong - High pull-out values: 132 lbs for 3/4 in (19 mm) chipboard, 161 lbs for MDF, 161 lbs for 5/8 in (17 mm) spruce and 187 lbs for 5/8 in (17 mm) veneer coated beech

- Versatile

- Works specifically well for components with small dimensions where nails would need to be used

- Case good elements can be transported in individual parts, where final assembly is carried out on site

- Ideal for CNC machining centers

- A high degree of prefabrication

- All kind of wood boards (solid and composite materials)

Tips:

- Perfect for industrial manufacturing with CNC

- Used with all wood and board materials

- Can be used as a clamping aid while the glue dries

- For inside and outside use

Applications:

- Clamping aid

- Case Goods

- Cabinets and drawer boxes

- Stairways

- Ship interiors

- Architectural Millwork

- Shop fittings

- Furniture

Threaded stud, plastic sleeve

none

2-part locking dowel

By screwing in the threaded stud and knock in the plastic sleeve

Concealed, self-tightening cabinet connector

Doweling jig, cordless drill, dowel inserting machine

All board materials (solid and composite)

Furniture, cabinetry, case goods, shop fittings

Installation

KNAPP-Dowel Installation

(View and Download Instruction Manual)

- Predrill boreholes

- If used with glue - add KNAPP®-Adhesive PU+ (Z011/1)

- Insert KNAPP®-Dowel using a dowel insertion machine or hammer in by hand

- Assemble workpiece with a rubber mallet

TUCK Installation

⇓View and Download TUCK Instruction Manual⇓

- Drill borehole according to the TUCK dowel size

- Insert the dowel into the surface (not into the edge) of the workpieces

- Brush the edges with glue (optional) and attach workpiece with a rubber mallet

*Note - Assemble components with a rubber mallet on the surface, but not necessarily from above against a hard surface; it is better to hit the surface from below and use the self-suspension of the material – this way the parts connect very fast. In the case of very large workpieces, a clamping aid might be needed. If glue is used it is not necessary to wait for the complete hardening of the glue. Once the desired end position has been reached, the clamping aid can be removed immediately.

QUICK-SET Installation

⇓ View and Download QUICK-SET Instruction Manual ⇓

- QUICK-SET 5 mm, the holes for the metal studs are drilled with a Ø of 5 mm and a Ø of 8 mm for the plastic sleeve. QUICK-SET 8 mm requires a Ø of 8 mm for the metal stud as well as the plastic sleeve.

- The drilling depth for the plastic sleeve must be 31 to 32 mm

- The plastic dowel is loosely inserted into the borehole without adhesive.

- After preparation with both components, the body or furniture parts are joined together with slight pressure or using a rubber mallet

You must be logged in to post a review.

Reviews

There are no reviews yet.